nevertheless, if you want transfers in either all black or all white, you can purchase our WALAOne just one coloration Transfers as a more cost-powerful option.

in advance of diving to the sizing and placement of warmth transfers, an knowledge of these essential terms will assist you to avoid confusion.

urgent: The cured film is positioned on to the fabric and pressed with exceptional DTF heat press options.

For raster photos, a minimal resolution of a hundred and fifty dpi is needed at the size you want to printed. For greatest success, we propose a dpi of three hundred or greater.

immediate-to-film warmth transfers also provide additional versatility when it concerns the types of garments it is possible to print on. common monitor printing usually calls for specialised inks or devices for printing on particular varieties of fabrics, like nylon or spandex.

This portion sets the foundation for comprehending ways to more info print DTF transfers effortlessly with Do it yourself approaches.

Altered cloth texture: DTF prints can sometimes alter the texture of the fabric. especially with larger sized prints, the printer period may well truly feel stiffer in comparison with the rest of it.

Vibrant and sturdy Prints: DTF transfers create lively colors with outstanding toughness. The prints are immune to washing and have on, making sure they maintain high quality eventually.

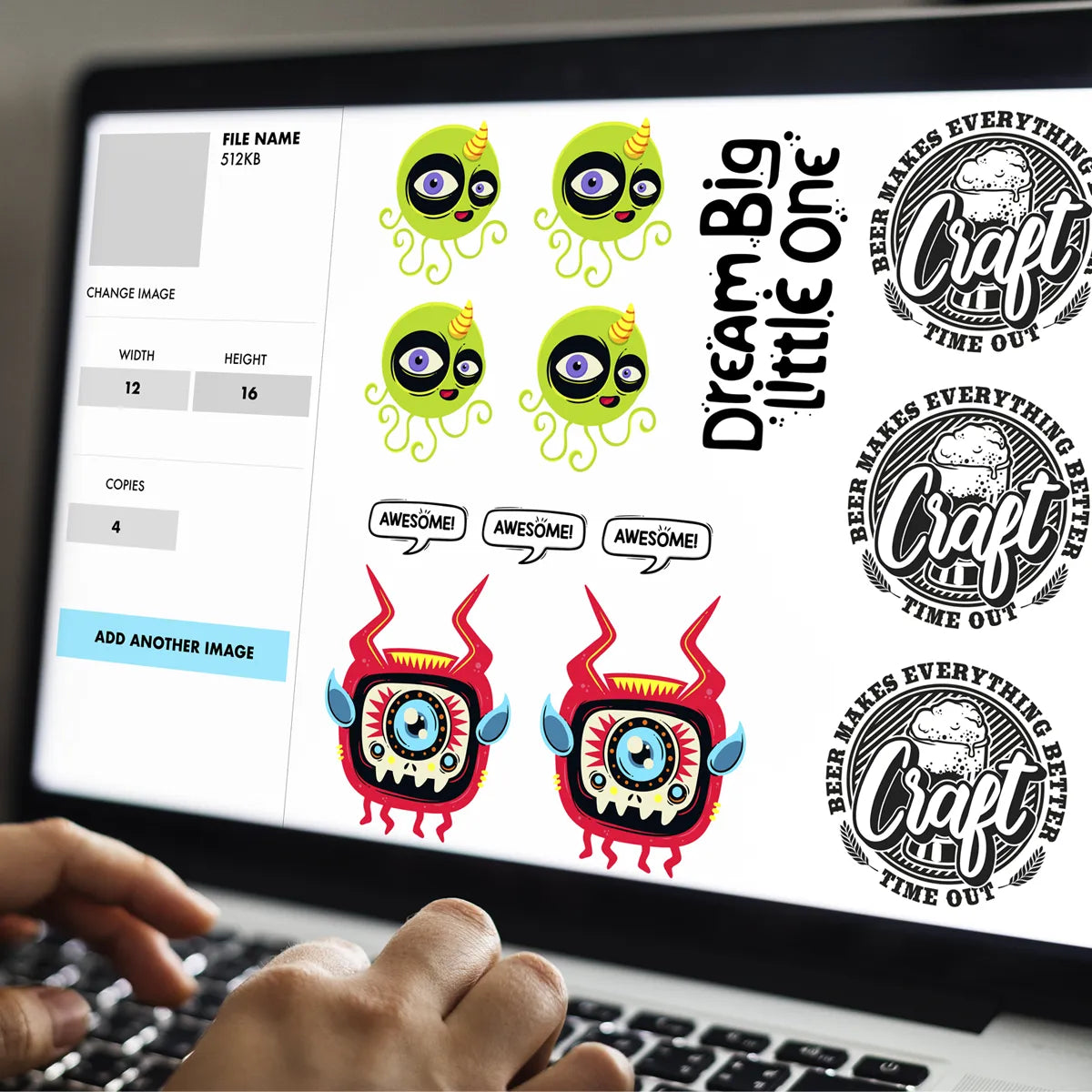

You need to use Completely ready-manufactured types or create custom made layouts in the electronic setting making use of design and style software package. Transfer your design to the DTF printer to execute the printing.

in advance of we dive into some great benefits of DTF warmth transfers, let’s initially outline whatever they are. DTF warmth transfers can be a kind of heat transfer technology that enables you to print high-quality, entire-color styles straight on to a transfer movie, that may then be heat pressed onto a garment.

software: Unlike screen printing, which includes a far more labor-intense system, DTF is much more clear-cut as outlined inside the “print DTF transfers quickly your DIY guidebook.”

the appliance of heat will cause the adhesive powder to soften and adhere to the ink, developing a reliable, transferable layer.

This printer utilizes drinking water-centered CMYK and white pigment inks to print the design in reverse. The white layer is printed last for a backing layer. This can make the colors to the substrate look extra lively.

With DTF printers, you can certainly accomplish the specified print since they are known for their exceptional print quality, and the application method can be very straightforward.